Understanding Labels on Liquid Rubber: Choosing the Right Material

Understanding labels on liquid rubber as they are the backbone of mold-making, offering unmatched versatility for artists, hobbyists, and professionals. These materials enable the creation of detailed, durable molds for a wide range of applications. However, understanding the types, properties, and market dynamics is crucial to choosing the right rubber for your project and budget. And I must admit even after 30 years of using such products I still have troubles understanding labels because products keep on changing or improving.

This guide covers the three main types of liquid rubbers that are normally used in crafts and many businesses—silicones, polyurethanes, and latexes—it explains the key numbers and terms, and helps you choose by understanding labels, the best material for various craft projects.

As an Amazon Associate, I earn from qualifying purchases.

This post contains affiliate links. If you make a purchase through these links, I may earn a commission at no extra cost to you.

Table of Contents

1. The Three Main Liquid Rubbers in Understanding Labels

Silicone Rubber

- Platinum-Cured:

- Durable, heat-resistant, and often food-safe.

- Ideal for reusable molds requiring intricate detail or exposure to extreme conditions.

- Excellent for long-term projects but comes at a higher cost.

- Tin-Cured:

- A more affordable option with good flexibility.

- Prone to shrinkage and degradation, especially in humid conditions.

- Best for simpler projects or short-term molds.

- Best For: Long-term molds, resin casting, and food-grade applications.

Polyurethane Rubber

- Qualities:

- Moderate durability and a wide range of hardness levels.

- Sensitive to moisture during curing but adaptable for medium-detail molds.

- Best For: Budget-conscious projects and quick prototypes where silicone costs may be prohibitive.

Latex Rubber

1. Qualities:

- Extremely flexible and cost-effective but less durable.

- Requires layering to build thickness and lacks precision for fine details.

- Best For: Lightweight, decorative projects like masks or ornaments.

2. Breaking Down Common Terms in Understanding Labels

Understanding labels and the terms associated with liquid rubbers helps you make informed choices:

- RTV (Room Temperature Vulcanizing):

- Refers to rubbers that cure at room temperature, requiring no specialized equipment.

- Ideal for hobbyists and professionals seeking convenience and ease of use.

- Platinum-Cured vs. Tin-Cured Silicone:

- Platinum-cured offers superior durability and is often food-safe, making it ideal for reusable molds.

- Tin-cured is more budget-friendly but less durable, with a tendency to shrink over time.

3. Understanding Labels & Key Properties

Tear Strength

- Measures a material’s ability to resist tearing when stretched.

- High Tear Strength: Essential for molds with intricate details or frequent use.

- Silicone, particularly platinum-cured, has the highest tear strength, making it ideal for detailed, reusable molds.

Shore Hardness

- Measures flexibility and stiffness on the Shore A scale:

- 10-20 Shore A: Very soft, ideal for capturing fine details.

- 30-40 Shore A: Flexible yet durable, suitable for most crafts.

- 50-60+ Shore A: Harder and more rigid, ideal for heavy-duty molds like concrete casting.

4. Choosing the Right Rubber for Your Craft Projects

Here’s a practical guide for selecting the best rubber for specific crafting applications, with cost-effective alternatives:

Soap-Making

- Best Choice: Platinum-Cured Silicone

- Food-safe and durable, withstanding high-pH soap bases. Perfect for intricate soap bar designs.

- Second Choice: Tin-Cured Silicone

- A budget-friendly option for simpler or short-term molds.

Candle-Making

- Best Choice: Platinum-Cured Silicone

- Heat-resistant and flexible, ideal for detailed pillar or novelty candles.

- Second Choice: Polyurethane Rubber

- Suitable for less intricate designs but may struggle with very high temperatures.

Food and Cooking Molds

• Best Choice: Platinum-Cured Silicone

• Why?: Platinum-cured silicone is inherently food-safe, heat-resistant, and non-toxic, making it ideal for molds used in baking, candy-making, and chocolate work.

• Applications: Perfect for creating custom cake toppers, fondant designs, or chocolate molds.

• Tip: Always verify that the product explicitly states “food-safe” by reading and understanding labels to ensure compliance with food safety standards.

• Second Choice: Tin-Cured Silicone (With Caution)

• Why?: Tin-cured silicone is typically not recommended for food contact unless specifically labeled as food-safe.

• When to Use: Only as a cost-effective option if the product is explicitly marked as food-safe

Resin Jewelry

- Best Choice: Platinum-Cured Silicone

- Captures fine details with high tear strength, ensuring durability over multiple uses.

- Second Choice: Tin-Cured Silicone

- A cost-effective option for simpler jewelry designs or small production runs.

Decorative Plaster Ornaments

- Best Choice: Tin-Cured Silicone

- Flexible and easy to demold, great for short-term or medium-detail projects.

- Second Choice: Latex Rubber

- Best for lightweight, low-detail designs when cost is a concern.

Concrete Planters

- Best Choice: Polyurethane Rubber

- Strong enough to support the weight of concrete while maintaining detail and shape.

- Second Choice: Tin-Cured Silicone

- Offers flexibility for intricate designs but may not withstand repeated casting.

5. Decoding Kit Sizes and Pricing by Understanding Labels

Kit Sizes

- Kits are typically sold by combined weight, including Part A (base) and Part B (curing agent).

- Example: A “1kg kit” includes 500g of each component.

Pricing Variations

- Reputable Sellers:

- Offer stable prices around £4–£8 per kilo for good-quality materials.

- Discount Platforms (e.g., AliExpress, Temu):

- List inflated “original prices” (e.g., £30 per kilo) with flashy discounts to £18–£24.

- Risks include diluted materials, misleading descriptions, or unreliable performance.

Practical Examples

A reputable supplier might offer a 1kg tin-cured silicone kit for £7/kg, while a discount seller lists it at £25 with a 30% discount, reducing it to £17.50. The discounted kit may seem cheaper but often lacks the quality and reliability of the higher-priced option.

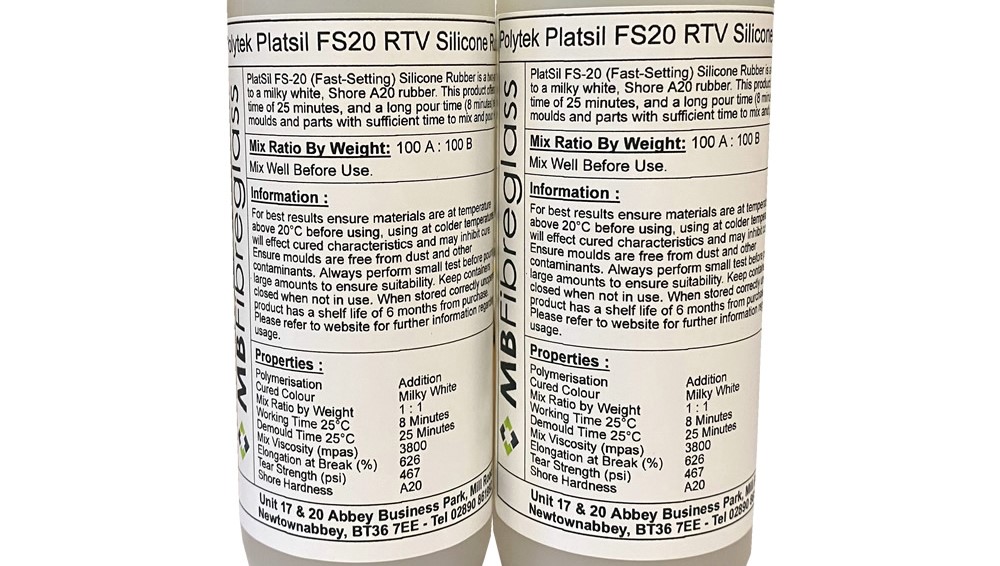

Interpreting a Product Label: An Example

Understanding product labels for liquid rubbers can feel overwhelming, especially with the technical terminology. Here’s an example of what a typical label might include, explained in straightforward terms:

Label Example: Key Specifications

- Mix Ratio (by Volume and Weight):

- 1A:1B – The two components (Part A and Part B) are mixed in equal amounts. This is standard for many liquid rubbers, making it easy to work with.

- Pour Time:

- 8 minutes – This is the time you have to work with the mixed material before it starts to set. Plan your workflow accordingly.

- Demold Time:

- 25 minutes – The time needed before you can safely remove the mold. Faster curing times like this are ideal for quick projects but may require careful handling during the pour.

- Cured Color:

- Milky White – While the cured color is cosmetic, it can affect how easily you see fine details in your mold.

- Mixed Viscosity:

- 4,200 cP – This measures how easily the material flows. Lower numbers mean better flow for intricate molds, while higher numbers might require more careful pouring.

- Specific Gravity:

- 1.11 – This helps calculate how much material you’ll need by weight. While useful for large-scale projects, most crafters focus on volume or weight alone.

- Elongation:

- 6.79% – This reflects the material’s ability to stretch before breaking. High elongation is valuable for molds that need to flex significantly.

Why These Details Are Useful but Not Always Critical

- For most crafters, core properties like Shore hardness, tear strength, and curing type are more practical indicators of a material’s suitability.

- Detailed specs like viscosity, specific gravity, and elongation are helpful for advanced users or niche projects but less critical for typical crafting applications.

By understanding how to read these labels, you can confidently choose the right liquid rubber for your project while avoiding unnecessary confusion.

6. Caring for Your Molds

To prolong the lifespan of your molds:

- Clean Properly: Use mild soap and water for silicone and polyurethane molds.

- Store Correctly: Keep molds in a cool, dry place away from direct sunlight or heat.

- Avoid Overstretching: Handle molds gently to maintain tear strength and prevent deformation.

7. Building a Mold Library with Silicone

For serious mold-makers, silicone, particularly platinum-cured, is the best investment for building a reusable mold library. Its durability, versatility, and ability to capture intricate details make it the material of choice for professional-grade molds.

Why Silicone Wins:

- Temperature Resistance: Handles hot materials like wax or chocolate without warping.

- Durability: Withstands repeated use without tearing.

- Long-Term Value: While more expensive upfront, silicone molds last significantly longer than latex or polyurethane.

Conclusion

By understanding the properties, types, and pricing of liquid rubbers, you can select the best material for your mold-making needs. Whether you’re crafting resin jewelry, soap, or concrete planters, aligning the right rubber with your project goals ensures professional results and maximizes your investment. With proper care and thoughtful planning, you can create molds that bring your creative ideas to life for years to come.

Contact Us

We hope you find the information on understanding labels on liquid rubber useful, but if you have any questions or need help, send us a message. You do have to sign in and confirm these days to comply with government rules. Sorry for the inconvenience.

Author Rob

Ps. This company below is the one that taught me how to build this website an 3 others in less than 6 months, they keep their promises.